Check out our latest blog below, from Refrigeration & Energy Solutions Manager Lee Harpham, who has spent 36 years working either in or closely with the engineering industry, about how, the sector is moving into a digital, green era, where a new wave of skills will be required.

The climate is changing, and governments and industries are all but unanimous in agreeing that now is the time to take action. There are exciting innovations across all industries that promise to usher in new, greener approaches and methodologies, from clean energy to sustainable manufacturing processes and automated efficiency.

The anticipated ‘green wave’ of innovation that will reshape the very fabric of our modern world can’t come soon enough. Whilst the focus has been on new technologies that reduce carbon emissions and energy consumption, the knock-on effect of this is that the engineers behind the machines that power our world are on the brink of an inevitable paradigm shift that will require them to adapt their skillsets and embrace a new era of knowledge. So, just how will all this innovation impact the engineers on the ground, especially in critical industries such as food retail and the cold chain?

Digitalising our food

Green innovation in the food retail industry is being driven predominantly by digitalisation, with technology being deployed across machines and infrastructure to monitor and control everything from temperatures to energy consumption in order to improve efficiency and reduce an asset’s carbon footprint. Access to raw, real-time health and performance data is available from digitalised assets, which provides opportunities to identify faults, failures, and trends to drive optimised operations and take automated corrective actions.

As the roll out of such technologies continues at rapid pace across the industry and across more asset classes, from HVAC systems to refrigeration, the potential opportunities that lie within their data sets only grows. Being able to view, contextualise and make changes to machines in real-time by understanding and leveraging their data can streamline maintenance, optimise energy consumption, mitigate food waste, and ultimately lower the carbon footprint of these machines.

To utilise such technologies and leverage the digital power embedded in new equipment, engineers will require the knowledge and understanding of how exactly to release this full potential. Think of it a bit like a digital toolkit: engineers now have a selection of digital tools available to enable advanced diagnostics and triage, early fault detection, root cause identification, parts management, historical context, and more all from the power of a handheld device.

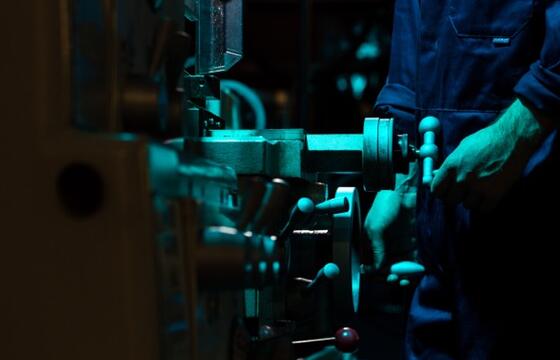

However, those carrying out critical maintenance in the retail sector will undoubtably always require the traditional on-the-tools maintenance skills, but it is becoming more and more critical for the modern engineer to have the knowledge base to manage, and the skill set to use the data from the systems and machines that are undergoing the digital transformation that is underpinning new, cleaner operations and processes.

Remote engineering

Throughout the Covid-19 pandemic, all industries that were adaptable to remote working made the transition from in-person to remote operations. Whilst this wasn’t always feasible for engineers, the rise of digitalisation and the empowerment this provided for maintenance personnel to remotely oversee critical metrics laid the foundation for the age of remote engineering.

With cutting-edge technology such as the Internet of Things (IoT) enabling mission-critical assets to be monitored and managed, engineers can see the real-time performance data, machine health insights, and active alarms and alerts from any site, no matter where they are. Engineers can conduct diagnostic tasks remotely and, in some cases, even execute remote fixes, thereby reducing the need for on-site visits and expediting the time it takes to address faults while verifying and protecting asset functionality and ensuring optimised performance – a win-win for sustainability.

There hasn’t been a ‘big bang’ of digitalisation in the food retail sector, but rather steady progress towards integrating technology and optimising processes. This has provided engineers with the time to learn new skills and adapt their approach to a green, digital era. But as this accelerates and we are on the cusp of finalising that move firmly into a future of digital assets, a new wave of skills and a new era for engineers is coming, and the industry must ensure they have the understanding to adopt the new digital toolkits on hand.